Furniture Manufacturing Made Easy

Integrated Design and Manufacturing

Design (PolyBoard), sheet optimization (OptiNest), and precision CNC routing in one system. Fewer errors, faster delivery, higher profits – with a smaller team.

Traditional furniture manufacturing is full of pitfalls

- Different design programs, manual drawings, parts lists → scattered information.

- Manual extraction of parts lists → risk of errors and time loss.

- Outsourced panel cutting → extra rounds and long lead times, lengthy repairs due to errors

- Post-processing → inaccuracy and extra work.

The solution: complete process in one system

- PolyBoard – parametric furniture design, 3D/2D drawings and CNC output.

- OptiNest – optimal sheet layout of parts from Polyboard, with minimal waste.

- Woodbox CNC router – machining and cutting individual parts according to OptiNest layouts.

Woodbox Benefits

Simplified Workflow

From design to finished furniture parts

Fewer Errors

Automated data exchange

Shorter Production Time

More projects undertaken

Material Savings

Optimized nesting

Higher Profit

With fewer workers

Simple Process – From Idea to Finished Furniture

The new era of furniture manufacturing in three steps

1. Furniture Design – PolyBoard

With the Polyboard furniture design software, you can easily create your furniture’s 3D plan and immediately provide quotes with detailed prices.

- Fast, rule-based design with customizable templates

- Automatic 3D/2D documentation and parts lists

- Direct data connection to OptiNest and CNC processes

The design process is easy to learn and much faster than using traditional CAD programs. Set the cabinet dimensions, then place the desired elements – drawers, doors, shelves and more…

Simple, Fast Design

The design process is easy to learn and much faster than using traditional CAD programs. Set the cabinet dimensions, then place the desired elements – drawers, doors, shelves and more. When dimensions change, the entire model updates automatically thanks to the rule-based design system. No need for a specialist to develop projects, making it ideal for small and medium-sized workshops.

Automated Calculations

Sloped walls and ceilings, irregular angles, and coverings around pipes are handled quickly and easily. Whether it’s simple cabinet boxes, L-shaped or corner cabinets, or free-form furniture – everything is possible.

PolyBoard’s efficient parameterization capability produces accurate manufacturing data every time, including all cutting angles.

Automatic 3D/2D Plans and Documentation

Individual cabinets can be easily placed in the project, for example when designing a room layout. This allows for accurate assessment of aesthetics, manufacturing possibilities, and proportions. Separate or composite worktops, back panels, plinths, and additional elements can be added, fully included in the cutting list, plans, and CNC files.

Parametric Cabinet Design

Machining of hinges, drawer slides, panel connections, and other hardware is done automatically based on placement rules you define, including precise configuration of drawers, doors, and additional elements. When resizing the project or modifying components, hardware is dynamically added, removed, or relocated according to current settings.

2. Sheet Optimization – OptiNest

Optimal placement of individual furniture parts on sheets has always been a challenge. OptiNest handles this completely automatically.

- Maximum material utilization with advanced algorithms

- Fast processing, shorter production time

- Integration with PolyBoard and woodbox CNC process

OptiNest’s true-shape algorithms fit parts of any shape tightly together, and can also use internal cutouts for smaller pieces. This allows more parts to fit on the same sheet, with fewer cuts and minimal waste…

Optimal Sheet Layout

OptiNest’s true-shape algorithms fit parts of any shape tightly together, and can also use internal cutouts for smaller pieces. This allows more parts to fit on the same sheet, with fewer cuts and minimal waste.

The optimization takes into account grain direction, rotation constraints, and mandatory distances to consistently achieve better material utilization and faster production.

Intelligent Remnant Management

The system saves remaining sheet sections so you can reuse them later. During the next optimization, these are automatically taken into account, requiring fewer new sheets.

Transparent inventory – by size, material, and grain direction – speeds up planning and further reduces cost and waste.

Production-Ready Documentation

The system generates automatic part labels (ID, edgebanding, rotation direction), so there’s no guesswork in the workshop. Detailed layout reports show material utilization and estimated production time, supporting planning and accounting. Export everything to PDF with one click for the workshop, speeding up throughput and reducing the chance of errors.

Manufacturing-Friendly Layout

OptiNest’s manufacturing rules enforce minimum spacing between parts, account for tool diameter in contour following, and apply necessary allowances/compensations. It supports common contour cutting and the use of tabs, resulting in fewer tool lifts and more stable holding during cutting. This results in shorter cycle time, fewer tool movements, and predictable, cleaner cutting quality.

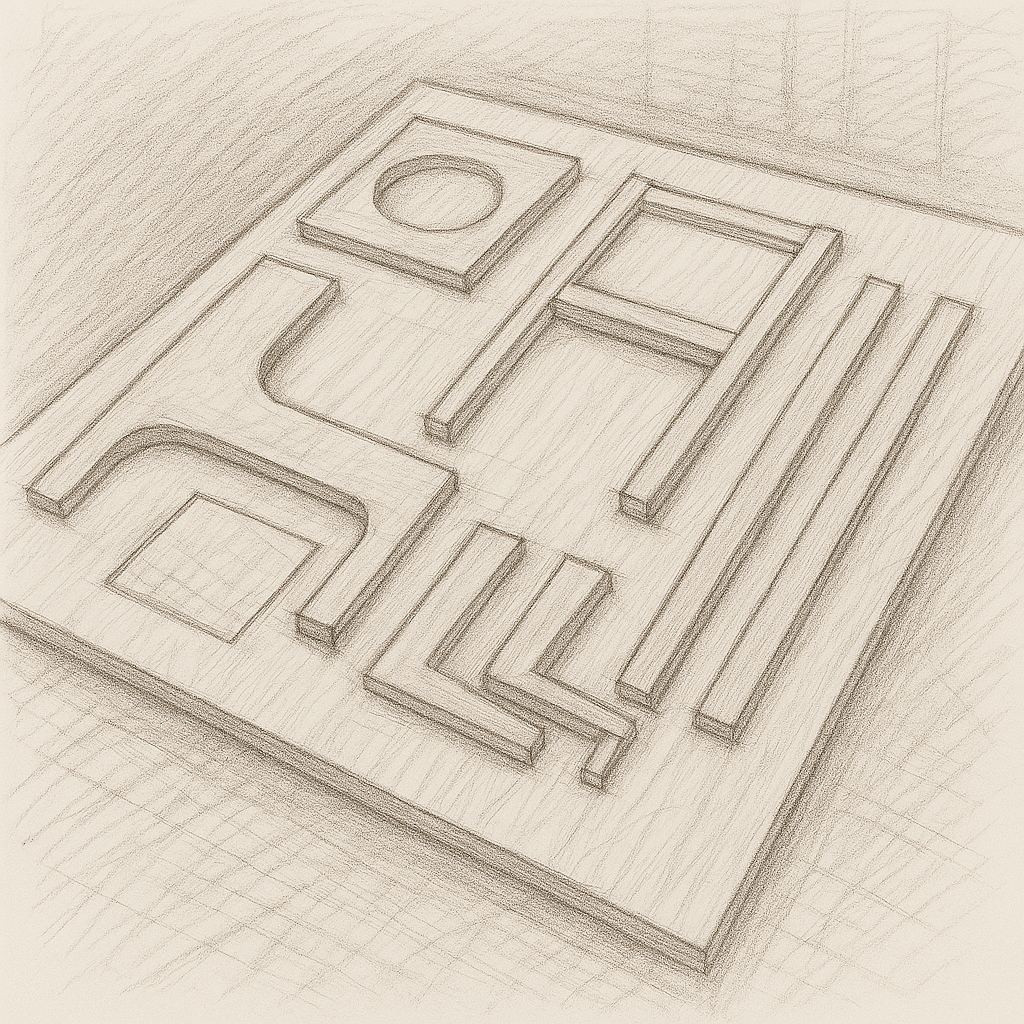

3. Machining – woodbox CNC router

The Woodbox nesting router works directly with data from OptiNest, allowing parts to be manufactured immediately from the sheet layout. Any shaped holes, pockets, engraving, and free contour cutting can be executed on the panel surface in one process. The single-chain data flow reduces manual intervention and the chance of errors.

The 2100×3000×200 mm work area covers furniture panel needs, rack-and-pinion X–Y and ball screw Z drive ensure ±0.2 mm accuracy throughout the entire range…

Precise Drive Chain

The 2100×3000×200 mm work area covers furniture panel needs, rack-and-pinion X–Y and ball screw Z drive ensure ±0.2 mm accuracy throughout the entire range. The 3 kW, 24,000 rpm spindle works with ER25 collets. Tool change is manual by default, but automatic tool changer (ATC) is optionally available.

Modular, Low-Cost Installation

The machine arrives in pieces, so the customer assembles it themselves, significantly reducing acquisition costs. The package includes detailed illustrated instructions and assembly videos, so if you’ve assembled IKEA furniture before, this won’t be a challenge. Of course, if requested, woodbox will provide on-site installation for an additional fee.

Fast Setup and Cleanliness

The tool height and length gauge speeds up setup and provides stable quality. The proprietary dust/chip extraction adapter with NA100 connection can be connected to a mobile dust collector or existing network, ensuring a cleaner and healthier work environment. Furniture panels are secured by default with manual clamping, but a vacuum table is available for quick securing.

Scalable, Workshop-Friendly Operation

The work area can be expanded in the Y direction at low cost, making parallel loading and unloading (pendulum operation) possible to reduce cycle time. The machine can operate from both 1- and 3-phase networks, so it can even be used in garage workshops. This provides real flexibility in terms of capacity and location.

Support

Machine Assembly

As soon as the delivered Woodbox arrives, we provide access to our assembly videos. These videos are designed to be easily understandable, covering all essential details while remaining short and focused.

Training

Post-purchase training materials are available to all our customers, as well as personalized training tailored to individual needs. For special requirements, we also provide on-site training at our own workshop.

Why Choose Woodbox?

Our team of passionate engineers and carpenters with decades of experience decided to reform the custom furniture manufacturing process. Our mission was to maximize the efficiency of our carpenters. Our work methods inspired other carpenters, so we decided to commercialize our solution for small and medium-sized carpentry businesses. Woodbox’s goal is to support the carpentry community and elevate furniture manufacturing to a new level (in terms of speed, quality, cost efficiency, and safety).

Our team is aware that Woodbox represents a significant investment for professional carpenters. That’s why we’ve created a comprehensive customer service system where our partners receive continuous support. If you would like to visit our workshop to personally try out the Woodbox, please share your contact information with the AI assistant below, and we will contact you to arrange an appointment.